FAMI are leading global producers of high-quality industrial and workshop furniture, with a rich Italian history that goes back 90 years. The company engaged 3CAD to facilitate sales ordinary activities and giving more time to focus on what they are best on: selling.

FAMI is a leading global producer of high-quality industrial and workshop furniture, with a rich Italian history that goes back 90 years. From their original workshop based under their home, they have now grown into an international supplier with four European branches and a network of international partners, all served from their 140,000 m2 headquarters in Rosà (Vicenza).

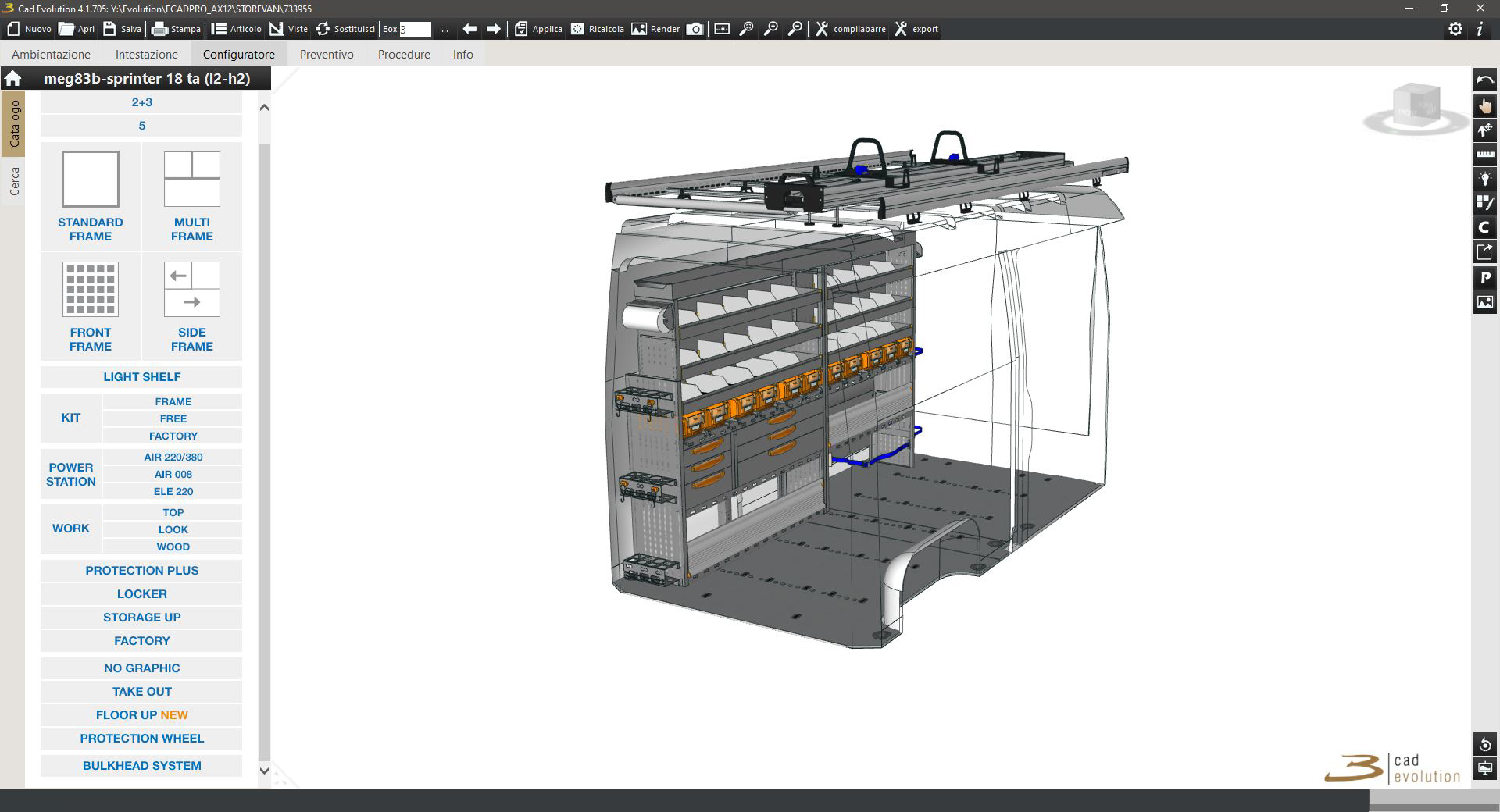

Since 2003, they have also entered the commercial vehicle outfitting sector, with the birth of the Store Van brand that serves the small craftsman, as well as the large commercial fleets.

To keep up with the needs of the market and tailor a personalized customer service, Luca Milani CEO of Fami reveals the secret of his success: the digitalization of their business. From marketing to production and from sales to order, the family-run business has seen its fantastic evolution thanks to cutting-edge software, including the adoption of the 3CAD product configurator.

The Challenge

Starting with the Store Van brand in 2010, FAMI wanted to find a solution to improve their sales process, so that they were ahead of the rest of the market.

At this point, the sales rep used their technical knowledge to create bespoke plans for each customer, based on the customer’s specific needs. This created a number of challenges:

- the sales team needed a lot of technical knowledge to create plans, which made recruitment harder

- the sales team were crucial to the fulfillment of each offer, which slowed down production

- details were often lost between sales and production, causing errors

- customization was bespoke, making mass production harder to achieve

All of these combined to create a blocker in expanding their sales and production of custom storage for vans.

The Solution

To overcome these challenges they engaged with 3CAD to harness their product configuration software. The first step was for our consultants to create a deep understanding of their business and the processes involved from sales all the way through to production.

Once they have this understanding, we are then able to convert the product range into a flexible database that will power the software and create a consistent link from configuration through to production. A key part of this database are intelligent parametric rules. These rules ensure that when the sales teams create new custom solutions, they can only plan what is possible to produce.

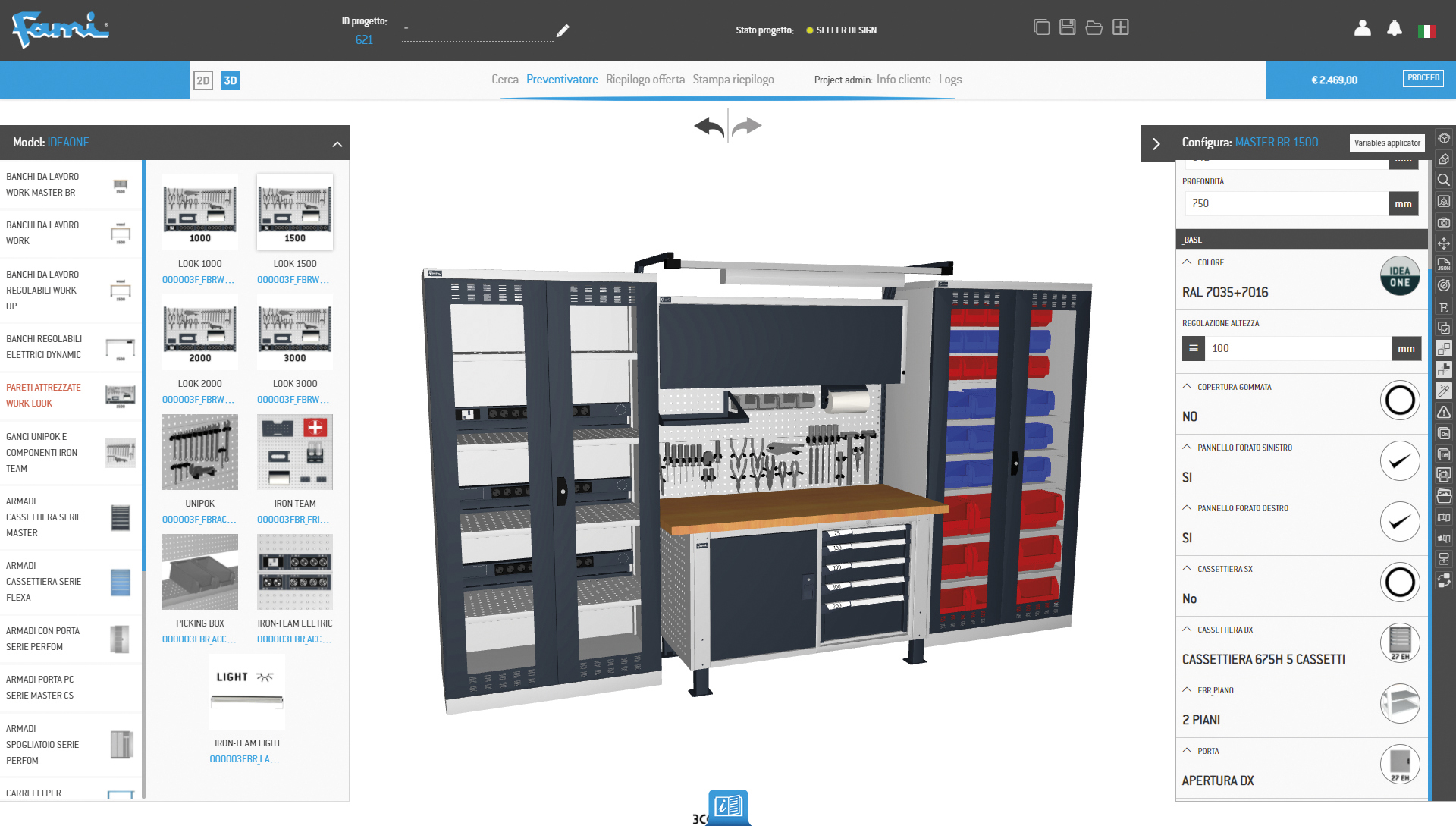

The result was the creation of a product configurator that is unique to the Store Van brand. Through this, sales teams are able to create custom storage solutions in a fraction of the time they were able to before. Thanks to the parametric rules, they are able to create bespoke solutions that can be easily produced at scale.

This allows the sales teams to focus on what they are good at: closing deals. They can then spend more time on driving more sales and less time on processing orders and creating plans.

Errors in production and dependency on sales knowledge are also removed. Once the design is created, then it can be ordered directly through 3CAD and sent to the production teams to process. It can even connect to production planning and ERP systems, to pass the relevant order and production details without losing any data.

This successful result convinced Fami to use 3CAD throughout the rest of their business. Now, whenever they look at a new product launch, they evaluate its configurability and ability to use it in 3CAD.

Professional wardrobes are now making use of 3CAD, including the ability to manage it through the cloud and connect it to their e-commerce platform. This will create a direct relationship and sales channel with customers.

A key factor in the success of this project has been the autonomy that the customer now has in implementing the solution to new products. Training of key staff within Fami means that they can use 3CAD for new products, with little assistance.

Secondly, but not least, the ability to create an accurate bill of materials ready for the production teams has dramatically shortened production times.

The concrete will of the company in the activation of the final part of its project, the clearing of the Fami configuration platform online, will allow a direct dialogue with the end-user concerned, thanks to the real-time approach, to the availability of real sales tutors and the possibility of immediate evaluation of the configuration possibilities, warehouse stocks, order times.

All this without forgetting the traditional ways of communication with your network, but by synchronizing them through contact points (QR code in the catalog for the single item to the product already configured – interactive PDFs – …) that increase the connection potential and the level of service provided.