CAPO D’OPERA is an example of excellence in textures, materials and design research, with a complete devotion in customised furniture solutions. 3CAD platform was a necessary step towards the optimal management of their processes and gave them the possibility to grow the numbers maintaining their unique products and identity.

CAPO D’OPERA is a high-end Italian lifestyle brand producing furniture, sanitaryware, accessories and a range of other things for the home, all with a focus on customisation. It is renowned for its extensive collection of beautifully crafted and curated textures and finishes – the consequence of many years of research and development into the latest trends and materials.

All the pieces in the collections are created by craftspeople before being machined, as mastering artisinal techniques is at the heart of the company’s ethos, which always aims for perfection.

The Challenge

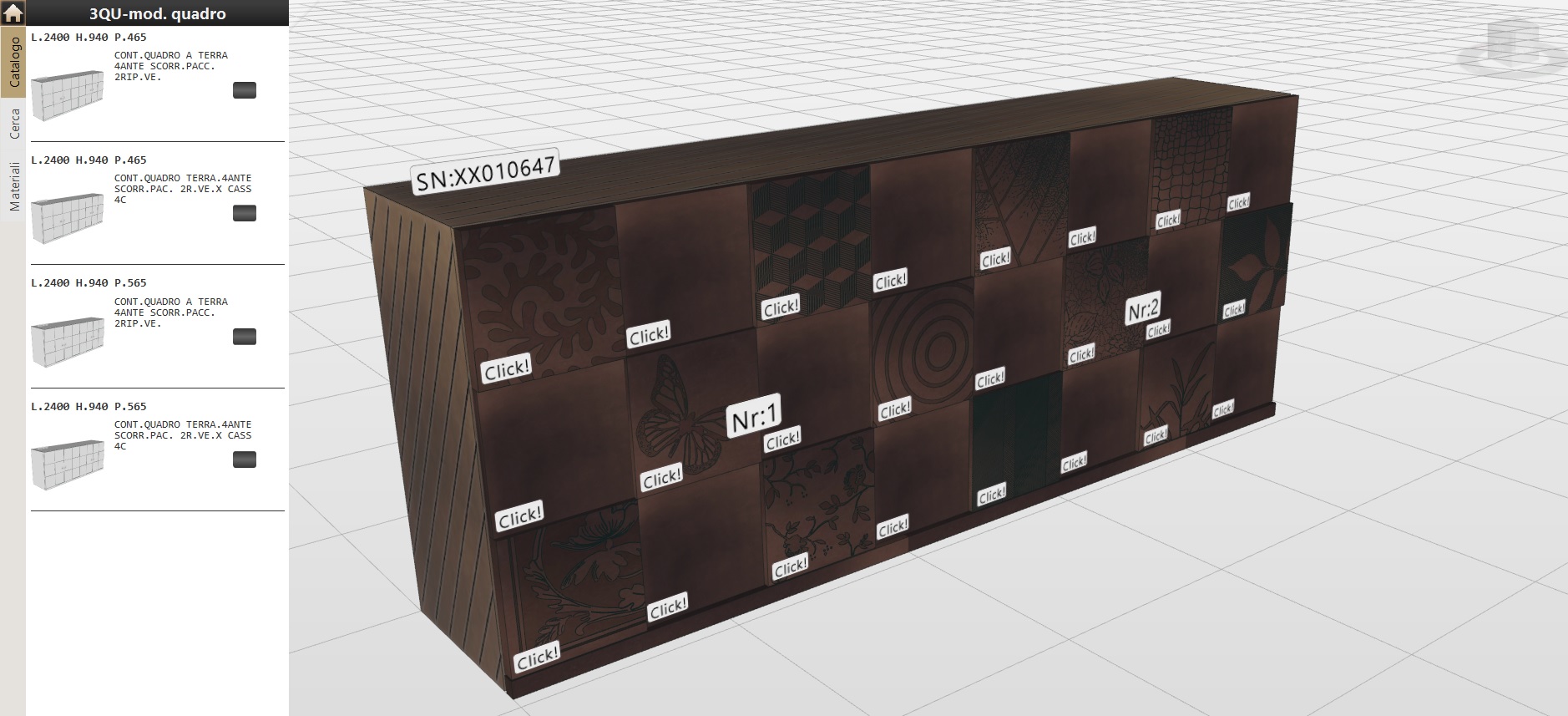

The Treviso-based company approached 3CAD in 2010, in response to a growing need for a software that could easily configure its modular, customisable furniture systems.

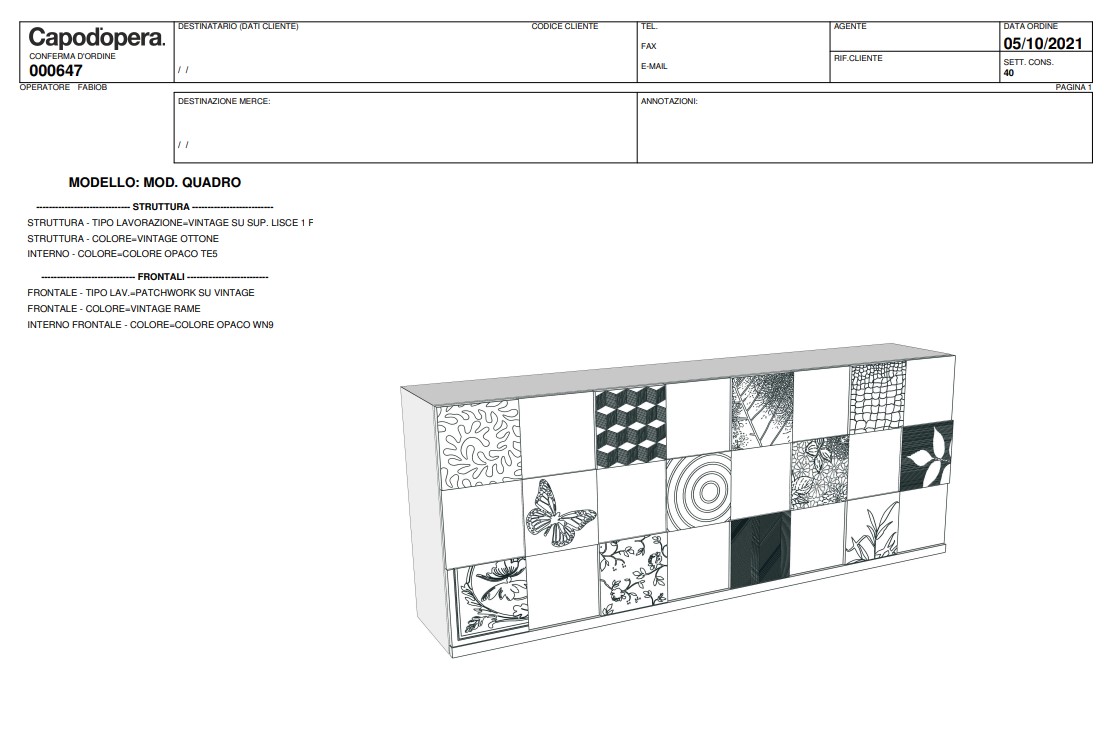

CAPO D’OPERA needed a software solution that could efficiently handle the customer’s order, while creating a blueprint or template which could be used to manufacturer the final piece. The problem was twofold – CAPO D’OPERA needed to commercially optimise to keep up with orders and maintain high levels of customer service and it also needed to simplify the production process by automating it through software.

Not having a warehouse of semi-finished products, every single object produced by CAPO D’OPERA is different from the others, made taking into account the quality of the entire production chain, starting from the raw material, to finish with the maniacal artisanal attention to detail during assembly and packaging.

The Solution

The 3CAD platform offered the solution as it enabled the company to increase production volumes by simplifying the sales process and automating the design process, with templates fed directly into the CNC machines.

The 3CAD team carried out an in-depth study into the rules and procedures that fed the CNC machines, before integrating the 3CAD software, enabling a seamless ordering-to-production process. Over the past three years, the integration has been refined, with other production elements added, including a specialised saw for intricate cutting work. In that case the graphic software, starting from the order and automatically, populates a shared table that allows to generate the files preparatory to the execution of the work, essential for the processing of data by the machine management software.

The presence of an internal dedicated person has thus customized the software over time to technical requests, just as the company behaves with its customers, solving in a capillary way the needs.

In addition to providing the usual 3D configuration possibilities, and making it easy for customers to customise products, the implementation of 3CAD has also enabled integration with the company’s proprietary management software.

As a consequence, the delivery times have been standardised and are the same for each customer, no matter the complexity of the order.